Главная страница » Portfolio » Steel shot » Acute-angled steel shot (SAE J444)

Steel grit (SAE J444)

DESCRIPTION

Specification

- Hardness: min. 60HRC;

- Packeddensity min. 7,2 g/cm3;

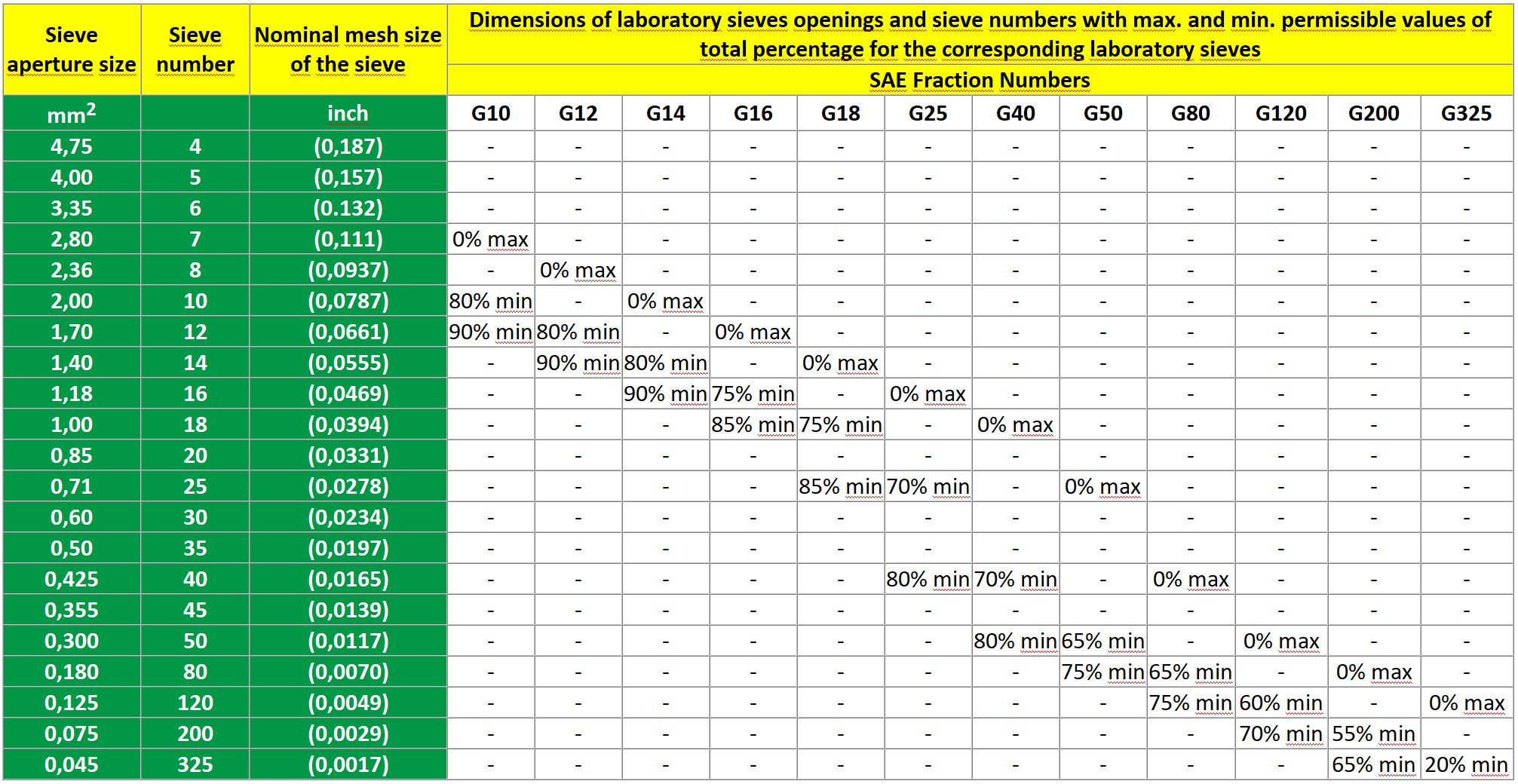

- Grain size in accordance to SAE J444;

- Packaging: 25 kg bags, 1000 kg bulk bags.

Chemical composition

- Carbon(C): 0,8 – 1,2%;

- Manganese (Mn): 0,6 – 1,2%;

- Silicon (Si): min. 0,5-1,0%;

- Sulphur(S): max. 0,05%;

- Phosphorus (P): max. 0,05%.

APPLICATION

Steel shot is used for cleaning of steel surfaces, cast iron and cast steel product, descaling and rust removal, de-burring.

ADDITIONAL INFORMATION

View Grain number – Nominal size in mm:

Other grades are available on request.

PRODUCT CHARACTERISTICS

Steel Grit : High-Performance Angular Media for Surface Treatment Offered by our company steel grit is a high-quality angular abrasive engineered for outstanding performance in surface cleaning, abrasive blasting, and preparation tasks. Produced using an advanced heat-treatment process, this abrasive offers exceptional strength, reliable precision, and consistent outcomes, making it a trusted choice across multiple industries.

Highlighted Features of Steel Grit:

- Low Electrical Conductivity: Helps prevent surface contamination, delivering safer and cleaner results;

- Engineered Microstructure: Built for extended durability and high operational performance;

- Variety of Sizes: Available in multiple size and hardness options tailored to specific applications;

- Sustainable Design: Supports environmentally friendly operations by minimizing waste.

Common Uses of Steel Grit

Steel grit is a multi-purpose abrasive commonly applied in:

- Blasting Operations: Effectively removes scale, rust, old coatings, and contaminants;

- Surface Conditioning: Prepares surfaces for coatings and painting with smooth, uniform finishes.

- Industrial Fastening Components: Used in the production of bolts, nuts, and weld accessories;

- Concrete and Ballast Applications: Acts as a heavy filler for counterweights and concrete structures;

- Metal Casting: Promotes better heat transfer and reduces impurities during foundry processes.

Advantages of Using Steel Grit

- High Productivity: Sharp, angular particles allow for faster cleaning and surface prep;

- Economic Efficiency: Long-lasting material life reduces overall consumption and maintenance costs;

- Global Supply Chain: Produced at multiple locations, enabling swift and reliable delivery worldwide;

- Flexible Applications: Custom hardness and sizing to fit diverse industrial demands.

Packaging Details

Steel grit is available in 25 kg bags in corton boxes on a wooden pallet 1000 kg. Every batch undergoes thermal treatment to guarantee maximum consistency and endurance.

Why Select Our Steel Grit?

Combining toughness, accuracy, and environmental responsibility, our product is the go-to solution for professionals in surface treatment, abrasive blasting, and specialized manufacturing. Its robust performance and sustainable production make it an optimal choice for achieving efficient, clean, and reliable results across a wide range of industrial sectors.