Главная страница » Portfolio » Steel shot » Cast steel shot (SAE J444)

Steel shot (SAE J444)

DESCRIPTION

Specification

- Spherical shape

- Hardness 40 – 51 HRC

- Packeddensity, min >7,2 g/cm3

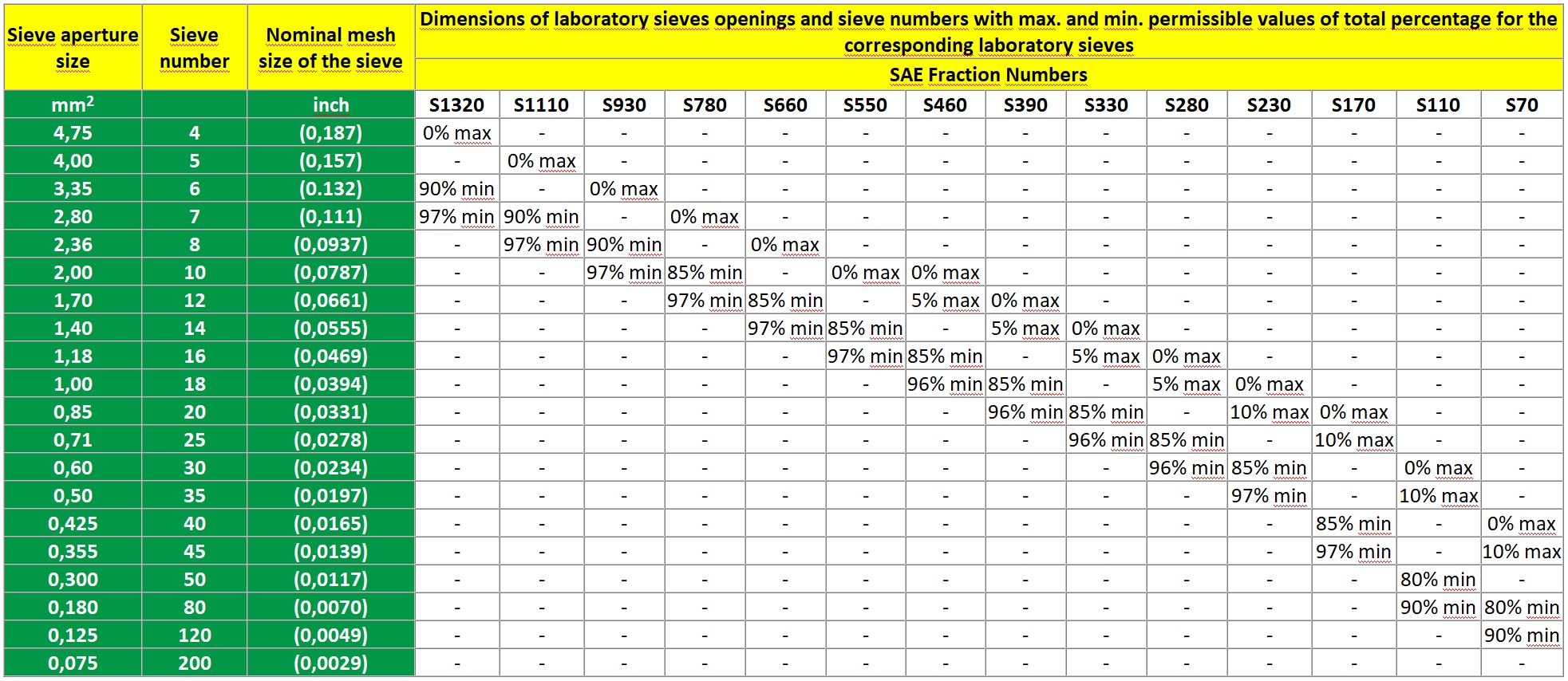

- Grain size in accordance to SAE J444

- Packaging: 25 kg bags, 1000 kg bulk bags.

Chemical composition

- Carbon (C): 0,8 – 1,2%

- Manganese (Mn): 0,6 – 1,2%

- Silicon (Si): 0,5 – 1%

- Sulphur (S): max. 0,05%

- Phosphorus (P): max. 0,05%

APPLICATION

Low carbon steel shot is used for cleaning of steel surfaces, cast iron and cast steel product, descaling and rust removal, de-burring.

ADDITIONAL INFORMATION

View Grain number – Nominal size in mm:

Other grades are available on request.

RELIABLE AND HIGH-PERFORMANCE SOLUTION FOR SURFACE TREATMENT

Steel shot is a round-shaped abrasive specifically engineered for surface preparation and abrasive blasting. Thanks to advanced heat-treatment technology and strict quality assurance, it offers excellent durability, consistent performance, and high efficiency. With multiple grades of hardness and grain sizes, it is ideally suited for cleaning, deburring, and prepping metal surfaces across a variety of industries.

PRODUCT OVERVIEW

Steel Shot offered by our company: Superior Spherical Abrasive for Industrial Surface Treatment

Offered material is a high-grade, round metallic abrasive specifically engineered for surface preparation and abrasive cleaning. Manufactured under strict quality standards and subjected to a specialized thermal treatment, it offers outstanding strength, elasticity, and operational efficiency. Ideal for cleaning, deburring, and prepping metal components, steel shot provides a dependable and cost-effective solution for a broad range of industrial uses.

Core Features of Steel Shot

- High Sphericity: Minimizes equipment wear and delivers stable, elastic performance;

- Refined Martensitic Structure: Ensures excellent durability and extended service life;

- Cost-Effective Manufacturing: Produced at global facilities to maintain affordability and quality.

Primary Applications of Steel Shot

Steel shot is highly adaptable and widely used in various sectors, including:

- Blasting Operations: Efficient at stripping rust, paint, and debris from metal surfaces.

- Surface Preparation: Prepares workpieces for processes like coating, painting, or welding;

- Industrial Component Manufacturing: Commonly used in making bearings, machinery, and foundry parts;

- Ballistic Applications: Valued in sports shooting, defense, and law enforcement for its consistent ballistic properties;

- Construction & Heavy Industries: Serves as a vital material in infrastructure and chemical processing projects.

Production Process of Steel Shot

Steel shot is created by melting high-quality steel scrap, which is then rapidly cooled using high-pressure water jets to form uniform spheres. These particles are screened by size, polished, and thermally treated to reach the required hardness range (typically 60 HRC). Every production lot undergoes thorough quality inspection to ensure optimal uniformity and durability.

Advantages of Steel Shot

- Efficient Cleaning: Round shape promotes uniform impact for even surface treatment;

- Longevity & Affordability: Extended product life helps lower material usage and operational expenses;

- Size Flexibility: Available in a range of sizes and hardness options to fit different applications;

- Environmentally Responsible: Manufactured using sustainable practices that reduce waste and environmental impact.

Packaging Options

Steel shot is offeredin 25 kg bags in corton boxes on a wooden pallet 1000 kg. This flexible packaging supports both small-scale and high-volume industrial needs.

Why Choose Our Steel Shot?

Combining resilience, precision, and economic value, steel shot from W Abrasives is a trusted abrasive solution across global industries. Whether you’re working in surface finishing, metal preparation, or specialized manufacturing, it ensures reliable, consistent results. With sustainable production practices and broad international distribution, offered steel shot stands out as the smart choice for modern surface treatment challenges.