Главная страница » Portfolio » Molded refractory materials

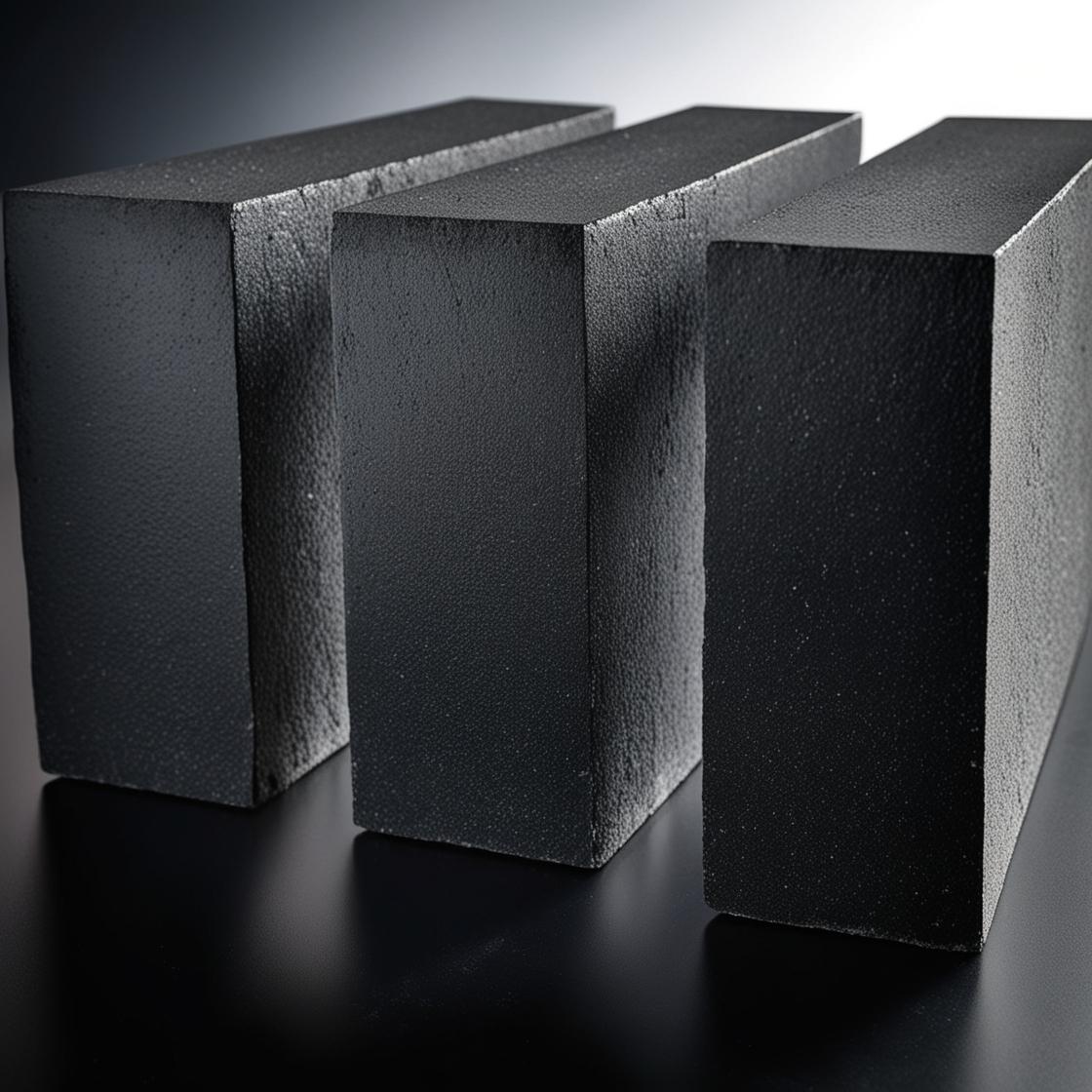

High-Quality Refractory Bricks Wholesale from GRUPA-PPW: Your Reliable Partner in Industrial Solutions!

In today’s demanding industrial environment, the need for high-performance, durable refractory materials is more important than ever. GRUPA-PPW stands at the forefront of this industry as a trusted wholesale supplier of premium shaped refractory products. Specializing in the distribution of various high-grade refractory bricks, our company provides tailor-made solutions to steel mills, foundries, cement plants, non-ferrous metallurgy enterprises, and glass manufacturers across the globe.

Why Choose GRUPA-PPW?

At GRUPA-PPW, we understand the critical role that refractory materials play in the efficiency, safety, and longevity of industrial processes. That’s why we offer a broad spectrum of certified, high-performance refractory bricks, manufactured to withstand the harshest thermal and mechanical stresses. Our expertise in logistics, technical support, and international supply chains ensures that we can meet the needs of clients in Europe, Asia, the Middle East, and beyond.

Our Product Range: Shaped Refractories for All Applications!

We proudly offer a comprehensive selection of shaped refractory materials, including:

- Magnesia Carbon Bricks (MgO-C)

Engineered for high-temperature environments like converters, electric arc furnaces, and ladles, our magnesia-carbon bricks offer superior thermal resistance, excellent spalling resistance, and optimal slag corrosion performance. - Magnesia Bricks (MgO)

Our magnesia bricks, composed primarily of high-purity magnesium oxide, are designed for applications in rotary kilns and steelmaking furnaces, providing exceptional thermal conductivity and chemical stability. - Magnesia-Chrome Refractory Bricks

Combining the benefits of magnesia and chromite, these bricks are ideal for non-ferrous metallurgy and cement rotary kilns, delivering excellent corrosion resistance under varying temperature conditions. - Magnesia-Spinel Bricks

With high mechanical strength and outstanding thermal shock resistance, magnesia-spinel bricks are widely used in steel ladles, cement kilns, and non-ferrous metallurgical furnaces. - Andalusite Bricks

Produced from natural andalusite, these bricks offer high refractoriness, great structural stability, and are perfect for thermal equipment linings. - Mullite Bricks

Known for their high load-bearing capacity and resistance to chemical attack, our mullite bricks are widely used in ceramic kilns and glass industry equipment. - Mullite-Corundum Bricks

Combining the benefits of mullite and corundum, these refractory bricks offer exceptional wear and erosion resistance in aggressive furnace conditions. - Corundum Bricks

Made from synthetic or fused alumina, our corundum bricks provide excellent performance in high-temperature environments, including incinerators, kilns, and reactors. - Fireclay Refractories (Chamotte Bricks)

Cost-effective and reliable, our chamotte (fireclay) bricks are suitable for various heat treatment furnaces, fireplaces, and boilers. - Lightweight and Ultra-Lightweight Products

Ideal for insulating layers in industrial kilns, our lightweight refractories reduce heat loss and energy consumption without sacrificing durability. - Stopper Equipment

We offer a wide range of stopper rods and nozzles for precise steel flow control during casting operations, manufactured to meet the highest standards of dimensional accuracy and wear resistance. - Various Types of Siphon Products

Custom-engineered siphon bricks and elements for ladle purging and secondary metallurgy applications, offering consistent performance and extended service life. - Purging Plugs for Secondary Metallurgy

Designed for efficient gas injection and homogenization during ladle refining, our purging plugs provide uniform gas distribution, improved steel quality, and increased furnace productivity. - High-Alumina Bauxite Refractory Bricks

Made from calcined bauxite with high alumina content, these bricks are ideal for applications demanding high refractoriness and mechanical strength.

Certified Quality & International Standards

All refractory materials supplied by GRUPA-PPW are rigorously tested and comply with international quality standards. We collaborate with ISO-certified manufacturers and ensure that each batch is quality-assured before delivery. Whether you are constructing new refractory linings or maintaining existing furnace infrastructure, our materials meet the exact specifications required by modern industries.

Invest in Reliability with GRUPA-PPW

Our team of professionals is ready to assist you in choosing the most suitable refractory materials for your specific needs. Whether you are involved in metallurgy, ceramics, or glass production, GRUPA-PPW has the expertise and inventory to support your operational goals.

Contact Us

To learn more about our full range of shaped refractories or request a commercial offer, contact our sales department directly. Partner with GRUPA-PPW — your trusted supplier of premium refractory materials for heavy industry.